Stainless steel is a popular material renowned for its corrosion resistance, durability, and aesthetic appeal. One of the key factors influencing the visual characteristics of stainless steel is its surface finish. The surface finish not only affects the appearance but also influences factors such as cleanliness, corrosion resistance, and ease of maintenance. In this article, we will delve into the various surface finishes of stainless steel, each designed to meet specific aesthetic and functional requirements.

- No. 1 Finish (Hot Rolled, Annealed, and Pickled):

- The No. 1 finish is achieved through hot rolling, followed by annealing and pickling processes. This finish leaves a dark, scaly appearance on the stainless steel surface. While it provides a scale-free product, it is not typically chosen for its aesthetic appeal and is often used in industrial applications where appearance is secondary to other considerations.

- No. 2D Finish (Cold Rolled, Annealed, and Pickled):

- No. 2D finish is achieved through cold rolling, annealing, and pickling processes. It results in a smoother, matte finish compared to the No. 1 finish. This finish is suitable for applications where a clean appearance is desired but a highly reflective surface is not necessary.

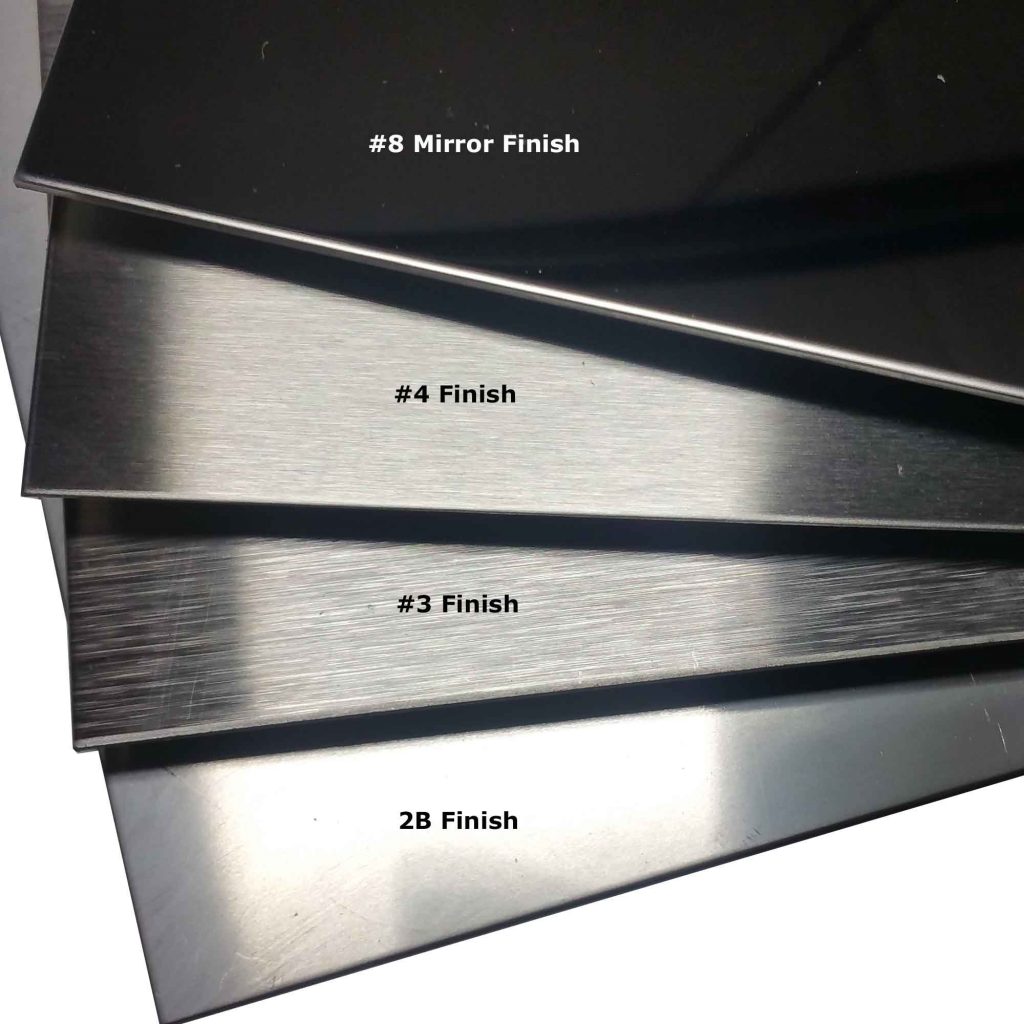

- No. 2B Finish (Cold Rolled, Annealed, and Pickled):

- The No. 2B finish is a widely used and versatile option. It provides a bright, semi-reflective surface that is smoother than the No. 2D finish. This finish is commonly used in kitchen appliances, architectural elements, and other applications where a moderate level of reflectivity is preferred.

- No. 3 Finish (Polished with 100-120 Grit):

- Achieved through polishing with 100 to 120 grit abrasives, the No. 3 finish results in a semi-polished surface. It provides improved surface smoothness compared to No. 2B, making it suitable for decorative applications, such as ornamental pieces and architectural components.

- No. 4 Finish (Polished with 150-180 Grit):

- The No. 4 finish is a popular choice for achieving a clean and polished appearance. It involves polishing the stainless steel with abrasives in the range of 150 to 180 grit. This finish is commonly used in kitchen equipment, decorative applications, and architectural elements.

- No. 8 Finish (Mirror Finish):

- The No. 8 finish is the highest level of polish achievable. It results in a highly reflective, mirror-like surface that enhances the aesthetic appeal of stainless steel. This finish is often selected for decorative items, architectural features, and high-end appliances.

Conclusion

In conclusion, the surface finish of stainless steel plays a crucial role in determining its visual appeal and functional characteristics. Whether it’s the utilitarian No. 1 finish or the elegant No. 8 mirror finish, each option caters to specific needs in terms of aesthetics, corrosion resistance, and ease of maintenance. Understanding the diverse surface finishes of stainless steel allows designers, architects, and engineers to make informed choices based on the requirements of their projects.