In the world of construction and engineering, hollow sections play a pivotal role. These tubular structures—whether square, rectangular, or circular—combine strength, efficiency, and aesthetics in one package. Their versatility has made them indispensable across industries, from architecture to machinery design.

What Are Hollow Sections?

Hollow sections are metal profiles with a hollow cross-section. They are primarily made from steel or aluminum, and they come in various shapes. The hollow core makes them lightweight while maintaining structural integrity. This balance makes them ideal for load-bearing and aesthetic applications.

Types of Hollow Sections

1. Square Hollow Sections (SHS)

- Shape: Equal sides (e.g., 50mm x 50mm).

- Features: Good balance between strength and aesthetics. Clean lines and symmetrical strength.

2. Rectangular Hollow Sections (RHS)

- Shape: Unequal adjacent sides (e.g., 100mm x 50mm).

- Features: Stronger in one direction, ideal for directional load applications.

3. Circular Hollow Sections (CHS)

- Shape: Tubular/round.

- Features: Excellent resistance to torsion. Aerodynamic and uniform stress distribution.

Materials Used in Hollow Sections

Hollow sections are manufactured in a range of materials to suit different environments, structural demands, and aesthetic preferences:

1. Mild Steel

- Most common material.

- Offers excellent weldability and formability.

- Ideal for general construction and mechanical use.

- Mild steel coated with zinc to prevent rust.

- Widely used in outdoor or corrosive environments such as fencing, sign posts, and outdoor structures.

- High corrosion resistance.

- Used in chemical plants, food processing, and marine applications.

- Adds aesthetic value for architectural elements.

4. Aluminium

- Lightweight and corrosion-resistant.

- Often used in transport, aerospace, and lightweight architectural features.

- Easier to fabricate but not as strong as steel.

- Steel shaped at room temperature, offering greater dimensional accuracy.

- Common in precision construction applications and light steel framing systems.

- Formed at high temperatures, providing better ductility and stress resistance.

- Suitable for heavy-load structural applications.

Key Uses of Hollow Sections

Hollow sections are used across many sectors due to their strength-to-weight ratio and adaptability:

- Structural Support: Beams, columns, and frameworks.

- Mechanical Engineering: Shafts, rollers, machinery frames.

- Transport: Chassis and frames in automotive and railway systems.

- Furniture: Lightweight, modern furniture frameworks.

- Agriculture: Equipment frames, greenhouses.

- Fencing and Gates: Durable and visually clean solutions.

Applications by Industry

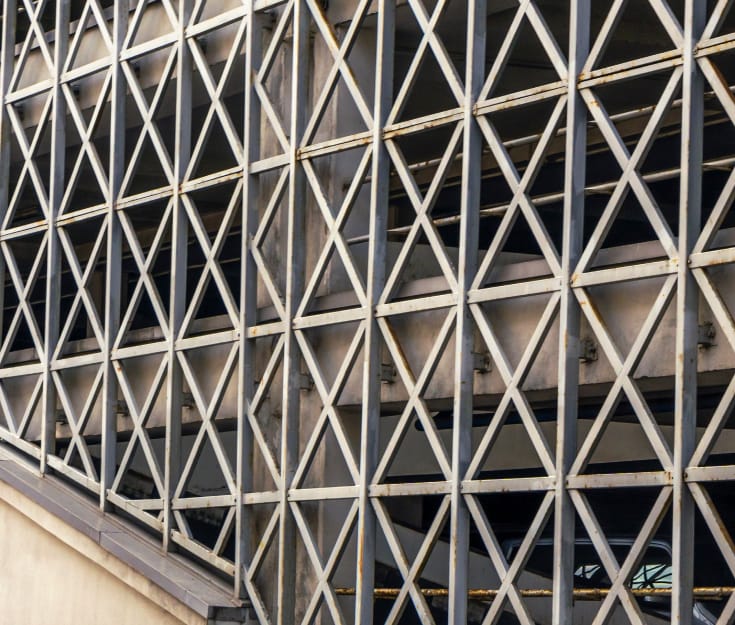

1. Construction

Ideal for frames, facades, and supporting members due to their load-bearing strength and clean aesthetics.

2. Infrastructure

Used in large-scale structures like bridges, walkways, and towers.

3. Automotive and Transport

Steel and aluminum hollow sections are integral to weight-efficient designs.

4. Renewable Energy

CHS structures are widely seen in wind turbines and solar panel supports.

5. Oil and Gas

Used for pipe racks, platforms, and offshore structures with high corrosion resistance requirements.

Advantages of Hollow Sections

- High Strength-to-Weight Ratio

- Corrosion Resistance (depending on material)

- Design Flexibility

- Efficient Transportation and Assembly

- Smooth, Aesthetic Appearance

Final Thoughts

The choice of hollow section shape and material can significantly impact a structure’s performance, cost, and longevity. With a wide range of types and materials available, hollow sections continue to offer smart, efficient solutions for structural and design challenges across every industry.