Introduction

Steel, a versatile and fundamental material in various industries, undergoes different manufacturing processes to attain specific properties. Three common methods include hot rolling, cold rolling, and cold drawing. Each method imparts distinct characteristics to the steel, making it crucial for manufacturers and engineers to understand the differences. In this article, we’ll delve into the nuances of hot rolled, cold rolled, and cold drawn steel.

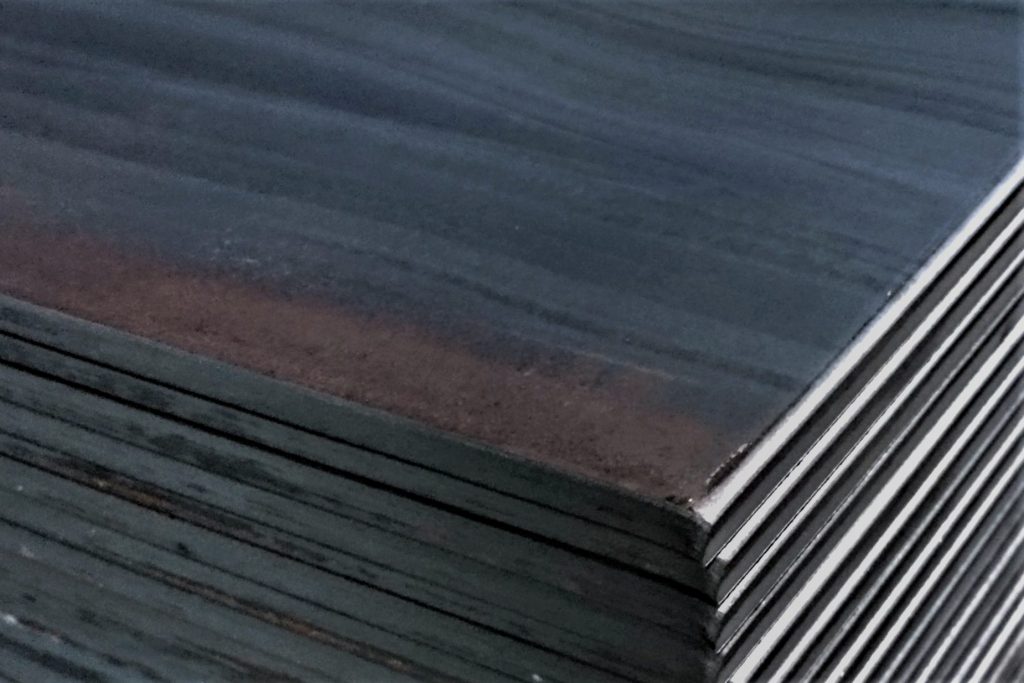

Hot Rolled Steel

Hot rolling is a manufacturing process where steel is heated above its re-crystallization temperature and then passed through rollers to shape it. This process results in steel with a scaled surface and a relatively rough finish. Hot rolled steel is known for its cost-effectiveness and quicker production times. It is often used in applications where surface finish is not a critical factor, such as structural components, railroad tracks, and sheet metal.

Advantages:

- Cost-effective production.

- Quick manufacturing process.

Disadvantages:

- Surface finish may be rough.

- Tolerance and dimensions may be less precise.

Cold Rolled Steel

Cold rolling involves passing hot rolled steel through a set of rollers at room temperature. This process produces steel with a smoother surface, tighter dimensional tolerances, and improved mechanical properties. Cold rolled steel is commonly used in applications that require a superior surface finish, such as automotive body panels, appliances, and furniture.

Advantages:

- Smoother surface finish.

- Tighter dimensional tolerances.

- Improved mechanical properties.

Disadvantages:

- Higher production costs compared to hot rolling.

- Slower production process.

Cold Drawn Steel

Cold drawing is a process that further refines cold rolled steel by pulling it through a die at room temperature. This process enhances the steel’s dimensional precision, surface finish, and mechanical properties. Cold drawn steel is often chosen for applications that demand high precision and strength, such as shafts, fasteners, and precision tubing.

Advantages:

- Superior dimensional precision.

- Improved surface finish.

- Enhanced mechanical properties.

Disadvantages:

- Higher production costs compared to cold rolling.

- Slower production process.

Comparison

- Surface Finish:

- Hot Rolled: Rough surface finish.

- Cold Rolled: Smoother surface finish.

- Cold Drawn: Superior surface finish.

- Dimensional Tolerances:

- Hot Rolled: Less precise.

- Cold Rolled: Tighter tolerances than hot rolled.

- Cold Drawn: Superior dimensional precision.

- Mechanical Properties:

- Hot Rolled: Good mechanical properties.

- Cold Rolled: Improved mechanical properties compared to hot rolled.

- Cold Drawn: Enhanced mechanical properties.

Conclusion

The choice between hot rolled, cold rolled, and cold drawn steel depends on the specific requirements of the application. While hot rolled steel is cost-effective and suitable for certain applications, cold rolled and cold drawn steel offer superior surface finish, dimensional precision, and mechanical properties, making them ideal for more demanding and precise applications. Manufacturers and engineers must carefully consider these factors to select the most appropriate steel manufacturing process for their intended use.