Galvanised Angle Bars

Galvanised Angle Bar

Information

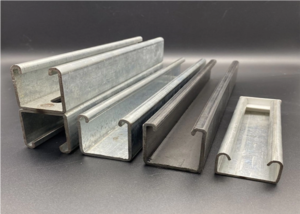

Galvanised angle bar, also commonly referred to as galvanised angle, galvanised angle iron, is a L-shaped low carbon steel bar with two equal or unequal legs that has been hot dipped in a zinc rich galvanizing process. Galvanised angle bars have great strength and corrosion resistance, therefore they are ideal for all general fabrication and repairs. Galvanised angle bars have also excellent weld performance, formability and machinability. As such, galvanised angle bars are often used in large structural settings such as high-rise buildings, bridges, transmission towers and factories.

Applications

Uses of galvanised angle bar include construction, transportation, structural applications, manufacturing, industrial, general fabrication, machining and repairs, transmission line towers and support frames.

Grades

Two of the common mild steel grades used for galvanised angle bars are EN10025 S275 and ASTM A36. EN10025 S275 is a popular mild steel grade utilized in various general engineering and construction applications. As a low carbon steel specifications, EN10025 S275 provides moderate strength with good machinability and can be easily welded. Mild steel grade S275 is used widely in the structural applications as it has good weldability and machinability.

Mild steel grade ASTM A36 is another popular and widely used carbon structural steels, which is mild and hot rolled. Grade ASTM A36 steel’s strength, formability and excellent welding properties makes it suitable for different kinds of machining processes. With its superior mechanical properties, ASTM A36 is usually the base material for all general construction and industrial applications. Depending on the thickness and corrosion resistance of the alloy, ASTM A36 mild steel is versatile and can be used for many different applications.

Common Grades, Sizes and Specifications

| Grades | Width | Length | Thickness |

|---|---|---|---|

| EN 10025 S275JR | Up to 350mm | Up to 6000mm | From 3.0mm |

| EN 10025 S355JR | Up to 350mm | Up to 6000mm | From 3.0mm |

| ASTM A36 | Up to 350mm | Up to 6000mm | From 3.0mm |

| BS4360 Gr43A | Up to 350mm | Up to 6000mm | From 3.0mm |

| JIS G3101 SS400 | Up to 350mm | Up to 6000mm | From 3.0mm |

Types

There are two predominant types of galvanised angle bars, hot-dip galvanising and electrogalvanising. For hot-dip galvanising, the steel surface is dipped in molten pure zinc. For zinc plating or electrogalvanising, a thin coating of zinc is applied on a steel surface using an electric current. Electrogalvanising produces a thinner less resilient surface and mostly recommended for interior use.

| Types | Description |

|---|---|

| Hot-Dip Galvanising | Application of a zinc coating by dipping steel in a molten pool of zinc. Alloy layers such as zinc oxide and zinc carbonate, are formed on the primary metal through reaction with the surrounding atmosphere to form a protect coating. |

| Electrogalvanising | An electrolyte solution is passed through an electric current, which is later applied to the steel. The electric current reduces positively charged zinc ions to zinc metal, which is then deposited on the positively charged steel. |

| Pre-Galvanising | Rolling sheet metal through a cleaning agent to quickly prime material for galvanising. The metal is passed through a pool of molten liquid zinc and is instantly recoiled. |

| Cold Galvanising | Application of zinc-rich paint to the surface of steel metal to protect it from corrosion. |

Other galvanised angle bar sizes and grades are available upon request. You can request to cut your galvanised angle bars down to size.

Kian Huat Metal

Kian Huat Metal is Singapore’s leading galvanised angle bar supplier with a wide distribution network that spans over 20 countries in the Asia Pacific region. With over 30 years of experience, we provide the very best quality products, prompt delivery and highest standard of services at competitive prices. At Kian Huat Metal, we supply an extensive range of metals for various applications. Our inventory includes: stainless steel, structural steel, mild steel, galvanised steel, aluminium, brass, bronze and copper. Our hot rolled and cold rolled steel is available in a wide range of shapes including: bars, rods, universal beams, universal columns, pipes, hollow sections, channels, sheets and plates. We can cut according to your exact specifications.

quality assurance

We ensure product quality and consistency through best practices and quality control that conform to local and international standards.

on time delivery

Our highly skilled team of drivers will ensure your orders are delivered within the time requested.

one stop shop

We offer a competitively priced and extensive range of steel products for all industries.

send an enquiry

If you have any questions related to our products or inquiry, we are happy to assist you. We will answer you via email as soon as possible. If you prefer to be contacted by phone, please leave your phone number. *

TRUSTED BY COMPANIES WORLDWIDE

All rights reserved